The GRS Guide System was developed to provide a highly accurate, universal surgical solution for the placement of dental implants combined with patented technology to make designing, fabricating and implementing dental implant surgical guides convenient, precise and affordable. Compatible with surgical drill systems from implant manufacturers worldwide, surgical guides can now be produced quickly and cost-effectively in-office or by a lab – with or without computer software – by either traditional vacuum/pressure forming and/or contemporary 3D printing.

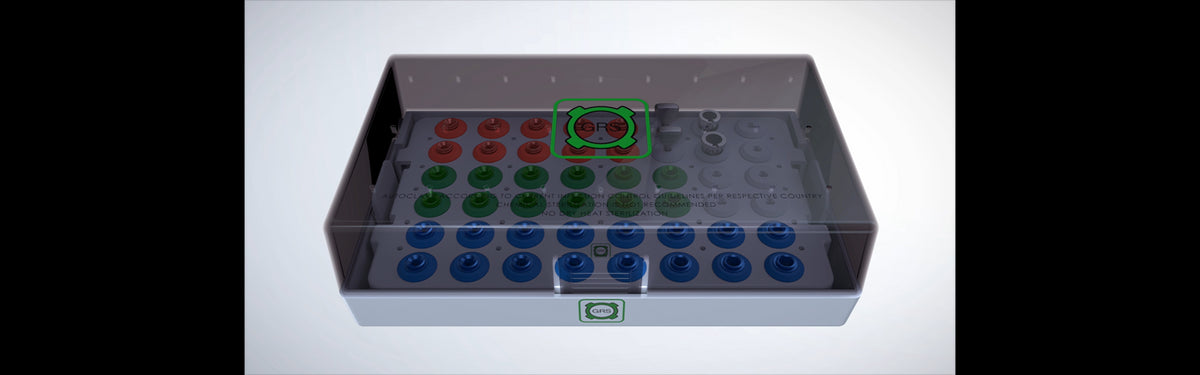

The GRS Guide System is a complete surgical system comprised of color-coded & numbered drill sleeves in graduated diameters to accurately guide a chosen surgical drill sequence and are easily snapped into and removed from a single, vacuum/pressure-formed and/or 3D printed GRS surgical guide. Unmatched in its versatility, the GRS Guide System’s low-profile surgical components provide for optimal posterior and anterior surgical access and can be used as a stand-alone surgical guide system or in combination with an implant manufacturer’s brand-specific surgical system for a nearly limitless range of surgical procedures.

The GRS Guide System is designed to ensure the utmost safety in all dental implant surgical applications and provides precise guidance for implant manufacturers worldwide including: Straumann, Nobel Biocare, Dentsply/Astra Tech, Zimmer/Biomet, Blue Sky Bio, Implant Direct, BioHorizons, 3M, Zest Anchors/Locator Implant System, and many more.

By integrating a universal guided surgery system with multi-platform surgical guide fabrication technology, the GRS Guide System is a paradigm shift in implant dentistry and provides the universal implant solution for the 21st century.

The GRS Surgical Guide Lab is dedicated to fabricating case-specific, highly accurate GRS surgical guides. 3D printed surgical models with implant holes for use in fabricating vacuum/pressure-formed GRS surgical guides are also available. Completed GRS surgical guides and surgical models are competitively priced and typically ship within 1-2 days, depending on case complexity.

| Straumann |

System Compatibility: Standard, Standard Plus, Bone Level Straight, Bone Level Tapered, Tapered Effect |

| Nobel Biocare |

System Compatibility: Nobel Active, NobelSpeedy (Replace | Groovy | Shorty), NobelParallel Conical Connection, Nobel Replace (Straight | Tapered | Select Straight | Select Tapered | Select TC | Select Tapered TC | Select PMC | Select Tapered PMC | Select Tapered Platform Shift | Conical Connection | Conical Connection PMC | Branemark MK III TiUnite | Branemark MK III Shorty | Branemark MK III Groovy | Branemark IV TiUnite) |

| Dentsply/Astra |

System Compatibility: OsseoSpeed (EV | TX | Profile), Ankylos (C | X), XiVE (S | TG) Narrow Body: 2.0mm, 2.5mm, 2.7mm. 2.9mm, 3.0mm, 3.1mm, 3.2mm, 3.4mm, 3.7mm, 3.8mm Regular Body: 2.0mm, 2.5mm, 2.7mm, 2.9mm, 3.0mm, 3.1mm, 3.2mm, 3.4mm, 3.7mm, 3.8mm, 4.2mm, 4.3mm, *4.4mm, 4.5mm Wide Body: 2.0mm, 2.5mm, 2.7mm, 2.9mm, 3.0mm, 3.1mm, 3.2mm, 3.4mm, 3.7mm, 3.8mm, 4.2mm, 4.3mm, *4.4mm, 4.5mm, 4.7mm, 4.9mm, *5.15mm Please Note: * Compatible With Dentsply/Astra Guided Surgery System Fixed OD Master Ring |

| Zimmer |

System Compatibility: Trabecular Metal | Screw-Vent Straight | Screw-Vent Tapered | SwissPlus Straight | SwissPlus Tapered | Advent | One-Piece |

| Blue Sky Bio |

System Compatibility: Bio-One Stage (Straumann Compatible) | Bio-Quattro (Straumann Compatible) | Bio-Internal Hex (Zimmer Compatible) | Bio-Conus 12 (Astra OsseoSpeed Compatible) | Bio-Three (Astra OsseoSpeed Compatible) | Bio-Trilobe (NobelReplace Compatible) | Bio-Max DP (NobelActive Compatible) | Bio-Max NP (NobelActive Compatible) | Bio-Max Mini (NobelActive Compatible) |

| Implant Direct |

System Compatibility: InterActive (NobelActive | Nobel Replace Conical Connection), Tri-Lobe (NobelReplace), Legacy (Zimmer Screw-Vent), Swish (Straumann Standard | Straumann Standard Plus), Spectra (Implant Direct Proprietary Product Lines) Narrow Body: 2.3mm, 2.8mm, 3.2mm. 3.3mm, 3.4mm, 3.5mm, 3.7mm, 3.8mm Regular Body: 2.3mm, 2.8mm, 3.2mm, 3.3mm, 3.4mm, 3.5mm, 3.7mm, 3.8mm, 4.0mm, 4.1mm, 4.2mm, 4.3mm, 4.4mm Wide Body: 2.3mm, 2.8mm, 3.2mm, 3.3mm, 3.4mm, 3.5mm, 3.7mm, 3.8mm, 4.0mm, 4.1mm, 4.2mm, 4.3mm, 4.4mm, 4.7mm, 4.8mm, 5.0mm, 5.1mm, 5.2mm |

| BioHorizons |

System Compatibility: Tapered Internal, Tapered Plus, Tapered Short, Tapered Tissue Level, Straight Internal, Straight Single Stage, Straight Laser-Lok, Straight External Narrow Body: 2.0mm, 2.5mm. 2.8mm, 3.0mm, 3.2mm, 3.4mm, 3.5mm, 3.7mm, *3.8mm Regular Body: 2.0mm, 2.5mm, 2.8mm, 3.0mm, 3.2mm, 3.4mm, 3.5mm, 3.7mm, *3.8mm, 3.9mm, 4.0mm, 4.1mm, *4.2mm, 4.4mm, 4.5mm Wide Body: 2.0mm, 2.5mm, 2.8mm, 3.0mm, 3.2mm, 3.4mm, 3.5mm, 3.7mm, *3.8mm, 3.9mm, 4.0mm, 4.1mm, *4.2mm, 4.4mm, 4.5mm, *4.6mm, 4.7mm, 4.9mm, *5.0mm, 5.2mm Please Note: * Compatible With BioHorizons Guided Surgery System Fixed OD Master Ring |

| BioMet 3i |

System Compatibility: |

| 3M/MDI |

System Compatibility: O-Ball & Square Head Narrow Body: 1.1mm, 1.7mm, 1.8mm, 2.4mm, 2.7mm, 2.9mm |

| Zest Anchors/ Locator Implant Systems |

System Compatibility: Locator (LODI) & Saturno Narrow Body: 1.2mm, 1.6mm, 2.1mm, 2.4mm, 2.9mm |